The newly started SUSPENS project, which kick-off meeting took place in the Jules Verne Institute in Nantes, addresses the challenge of reducing the environmental footprint of sandwich and hollow composite structures for the automotive, leisure boat and aerospace industries. The project consortium will take the mechanical performance of bio-based ingredients such as epoxy and polyester resins combined with natural and recycled fibers to an industry standard. The project will also focus on reducing the energy needed for the recycling of complex sandwich/hollow structures.

The SUSPENS project will develop over 95% bio-sourced epoxy and polyesters resins, with new formulations leading to high performance in a short cycle. These resins will be combined with sustainable reinforcements made with natural fibres (cellulose), lignin-based carbon fibre and recycled carbon and glass fibre to make sandwich and hollow parts for surface transport and aerospace industries.

Recycling solutions for such structures will also be developed in the project to cover the entire life cycle of the target applications. An innovative approach for a matrix pyrolysis will use the high temperature waste stream released by the carbon fibre transformation process to reduce drastically the energy consumption. In the meantime, a specific solvolysis will be developed to separate the biobased resins from the fibres. The valorisation of oil and organic components generated will be studied to transform them into by-products.

The general project approach will be demonstrated through the manufacturing and reclaiming of representative parts such as a car battery pack, a leisure boat deck and hull and an aircraft winglet.

A holistic life cycle analysis will support the demonstration by measuring the gains obtained on the environmental impact on the cradle-to-cradle cycle for all three applications.

Megara Resins is a specialty chemical company focused on the creation of novel processes for the cost advantaged production of chemicals from renewable feedstocks and important building blocks for a wide range of functional materials. The company’s goal is to produce the same chemicals that are currently produced from petroleum, but to do so from renewable feedstocks, at lower cost, by employing sustainable, low carbon footprint, environmentally friendly process technologies. The project fits perfectly with the company’s strategy to continuously targeting new markets and developing novel products as it transforms into a renewable materials company for the cost advantaged production of chemicals from renewable feedstocks.

The implementation of SUSPENS will accelerate some of the developments Megara Resins is working on and will provide a solid platform to move further in building a portfolio of sustainable bio-based solutions for its customers. The company’s objective is in line with European Commission’s bioeconomy policy that significant growth is expected to arise from sustainable primary production and industrial biotechnology and biorefineries, which lead to new bio-based industries, transform existing ones, and open new markets for bio-based products.

The role of Megara Resins is the synthesis and characterisation of bio-based unsaturated polyester resins (UPRs) for composites. The monomers for polyester synthesis will be chosen carefully, focusing on sustainability of the raw materials and their commercial availability. The aim will be to replace fossil-based reactive diluents and reactants commonly used for UPR synthesis. The possibility of substituting styrene, which usually acts as a reactive diluent, with a greener and safer alternative during the crosslinking of UPRs, will also be explored. Various potentially bio-based materials will be evaluated as styrene replacement in UPRs with sustainable non-harmful materials. The synthesized UPRs will be characterised in terms of their thermal, mechanical and physical properties. The suitability of the materials to be used for composites for automotive and building applications will be assessed in order to establish the potential for replacement of the conventional unsaturated polyester resins from petroleum sources. Life cycle assessment will be performed on selected UPRs, and comparison with a reference fossil-based UPR resin in terms of the calculated category indicator results will confirm the lower environmental impact of the newly prepared bio-based polyesters.

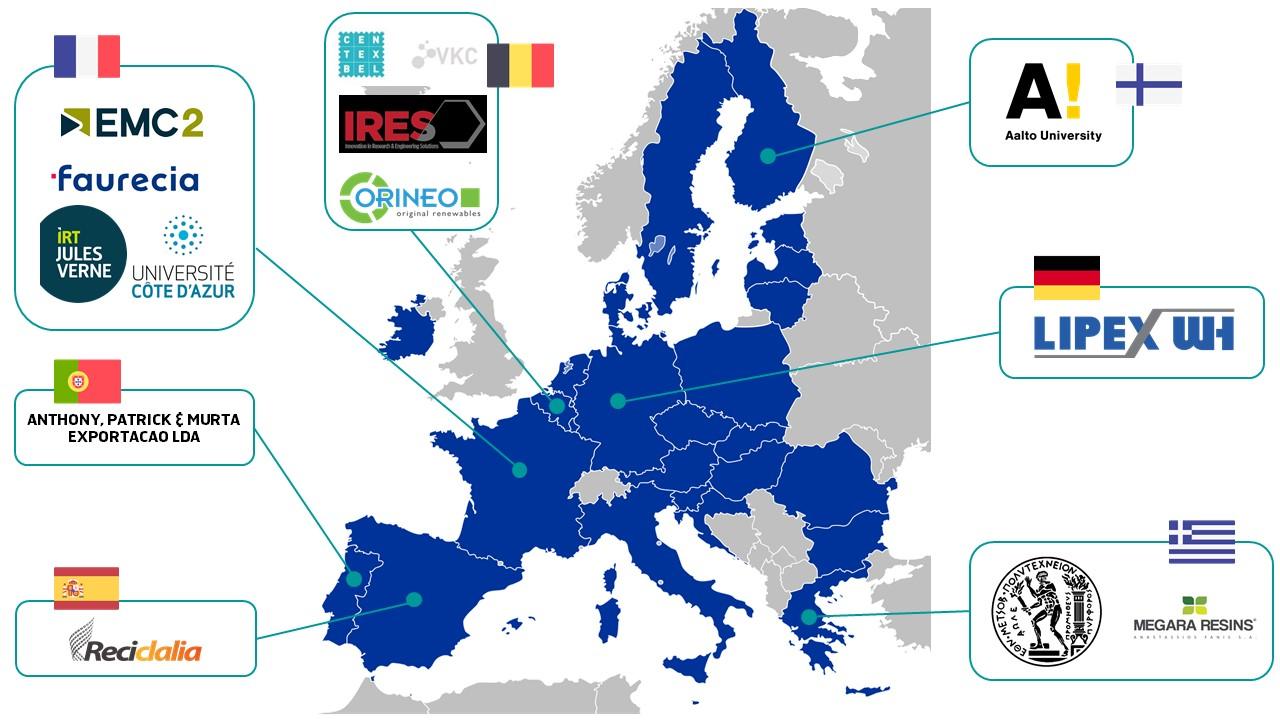

The SUSPENS project, co-funded by the European Union’s Horizon Europe programme, will last 42 months from January 1st 2023. SUSPENS brings together a consortium of 13 partners from 7 EU countries and is coordinated by IRT Jules Verne (France).

Project key figures

Total budget: 4.9 M€

Duration: 42 months

Partners: 13 partners from 7 EU countries (project coordinator: IRT Jules Verne, France)

Project partners

- INSTITUT DE RECHERCHE TECHNOLOGIQUE JULES VERNE (FR)

- CENTRE SCIENTIFIQUE & TECHNIQUE DE L’INDUSTRIE TEXTILE BELGE ASBL (BE)

- AALTO KORKEAKOULUSAATIO SR (FIN)

- ETHNICON METSOVION POLYTECHNION (EL)

- FAURECIA AUTOMOTIVE COMPOSITES (FR)

- ORINEO BVBA (BE)

- ANTHONY, PATRICK & MURTA-EXPORTACAO LDA (PT)

- RECICLALIA SL (ES)

- INNOVATION IN RESEARCH & ENGINEERING SOLUTIONS (BE)

- UNIVERSITE COTE D’AZUR (FR)

- WH Lipex GmbH (DE)

- MEGARA RESINS S.A. (EL)

- POLE EMC2 (FR)

Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the European Health and Digital Executive Agency (HaDEA). Neither the European Union nor the granting authority can be held responsible for them.

Project: SUSPENS